How are Dunhill Tobacco Pipes Made?

2nd Dec 2020

When Christopher Columbus first discovered America he also discovered the tobacco pipe. The pipe was an essential part of native culture, to be shared during times of negotiation and celebration.

Columbus and other explorers brought the concept home and history was made!

Since the 19th-century pipes have been made from Briar, a hard fire-resistant wood from the root of a Mediterranean heather shrub.

For this post, we will discuss how Dunhill pipes were created and why they still continue to be a premier tobacco pipe on the market today.

The Pipe Making Process Explained

After the Briar has cured for several months the pipe maker saws it into a rough pipe shape using a lathe and chisel they round the larger block to approximate the shape of the pipe bowl. They will then bore through the centre to carve out the tobacco chamber.

The stem will then be slimmed down, marking the centre for drilling later. The platemaker finalises the shape by hand and will then sand both the inside of the tobacco chamber and the outside of the pipe bowl. Next, the pipe’s mouthpiece will take shape with the pipe-maker piercing a piece of hardened rubber called Vulcanide to establish the centre and then drills a channel through it using a grindstone they sculpt one end taking it from brown to oval, a shape that fits more comfortably between the lips.

The pipe maker checks their work with the sizing template then shaves the exterior of the mouthpiece reducing it considerably and shaves the other end to form the tenon which fits into the pipe stem.

They will then polish the tenon with a special compound with the smoother surface making it easier to join to the pipe stem. Using a series of sanding discs with progressively finer grit they give the exterior of the mouthpiece a sleek finish.

It is then steadied in a clamp with the hole in the centre widened to broaden it into a funnel-shaped cavity. Attention now turns to the seam between the rubber and wood parts that are sanded to make them perfectly flush. Hand filing removes blemishes and adjusts the thickness for a more comfortable bite with the thickness easily customised for individual requirements. A tiny hole is drilled into the top of the mouthpiece then a plastic rod is dipped into glue and inserted in the hole. It is sanded down leaving a white spot, which indicates the mouthpiece is right-side up.

For bent or curved pipes, the mouthpieces are heated in an oven which makes the vulcanise flexible enough to be shaped by hand. Then the pipe maker will bend the mouthpiece to the desired shape with a quick hold down in water re-hardening the vulcanite, fixing its curve.

The wooden part of the pipe is buffed, which removes any fine scratches and brings out the wood grain and gives the wood a glossy finish. For different finishes, a craftsman will sandblast the Briarwood giving it a ripple texture. It is then stained darker using alcohol-based dye working the stain into every crevice. The pipe is then set on fire and the alcohol burns off to set the stain. The pipe does not go up in flames proving how fire-resistant it is. Up to ten layers of stain are burnt into the pipe, depending on the desired effect.

Finally, the company name is stamped onto the pipe and following a final quality inspection, these hand-crafted Dunhill Pipes are ready for pipe enthusiasts all over the world.

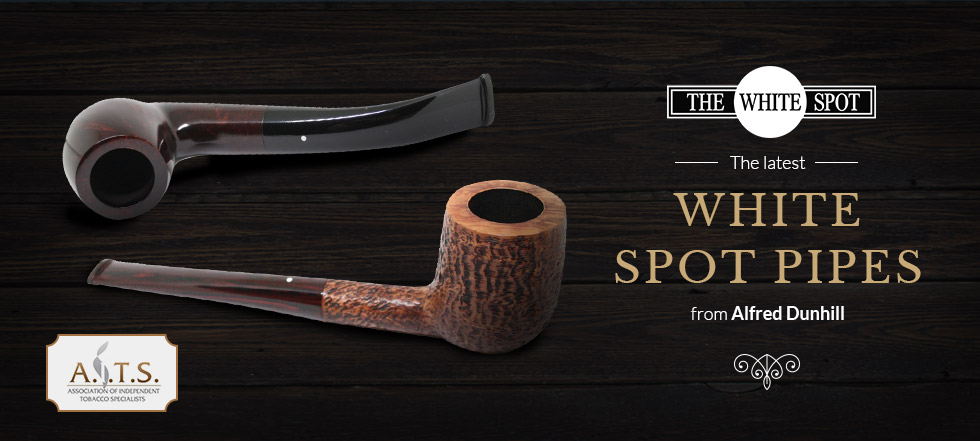

Order Your Dunhill Pipes from GQ Tobaccos

You can order the latest Alfred Dunhill pipes from GQ Tobaccos, if you have any questions please do not hesitate to contact us now.